SET ASSEMBLY KIT

The SET ASSEMBLY KIT is an ongoing project for Alberta Ballet. This represents the first iteration of the design process.

During a budget analysis, Alberta Ballet realized that their strategy for building, storing, and deploying sets was inefficient and outdated. New sets for Alberta Ballet productions were made as a collection of purpose-built pieces, which were then stored in a warehouse for years before the same production was mounted in a later season. Further, most pieces were built as complete entities, without much consideration for efficient transportation and ability for storage. Vast amounts of warehouse space were leased for the sole purpose of housing old sets, and the warehouse was bursting at the seams.

While the idea of a kit-of-parts is not new, and various off-the-shelf products are available for such purposes, the Ballet identified two key requirements specific to their needs that ruled out most ready-made systems. Firstly, the kit had to accommodate a diversity of angles; set design often uses trompe-l’oeil and forced perspective to create the illusion of depth on stage, resulting in sets that are often built with non-orthogonal geometry. Secondly, the kit had to include a limited number of individual part types, so that a small number of pieces could provide a wide variety of uses; there was a desire to avoid a proliferation of specialized pieces, which would lead to increased cost and disorganization in the workshop.

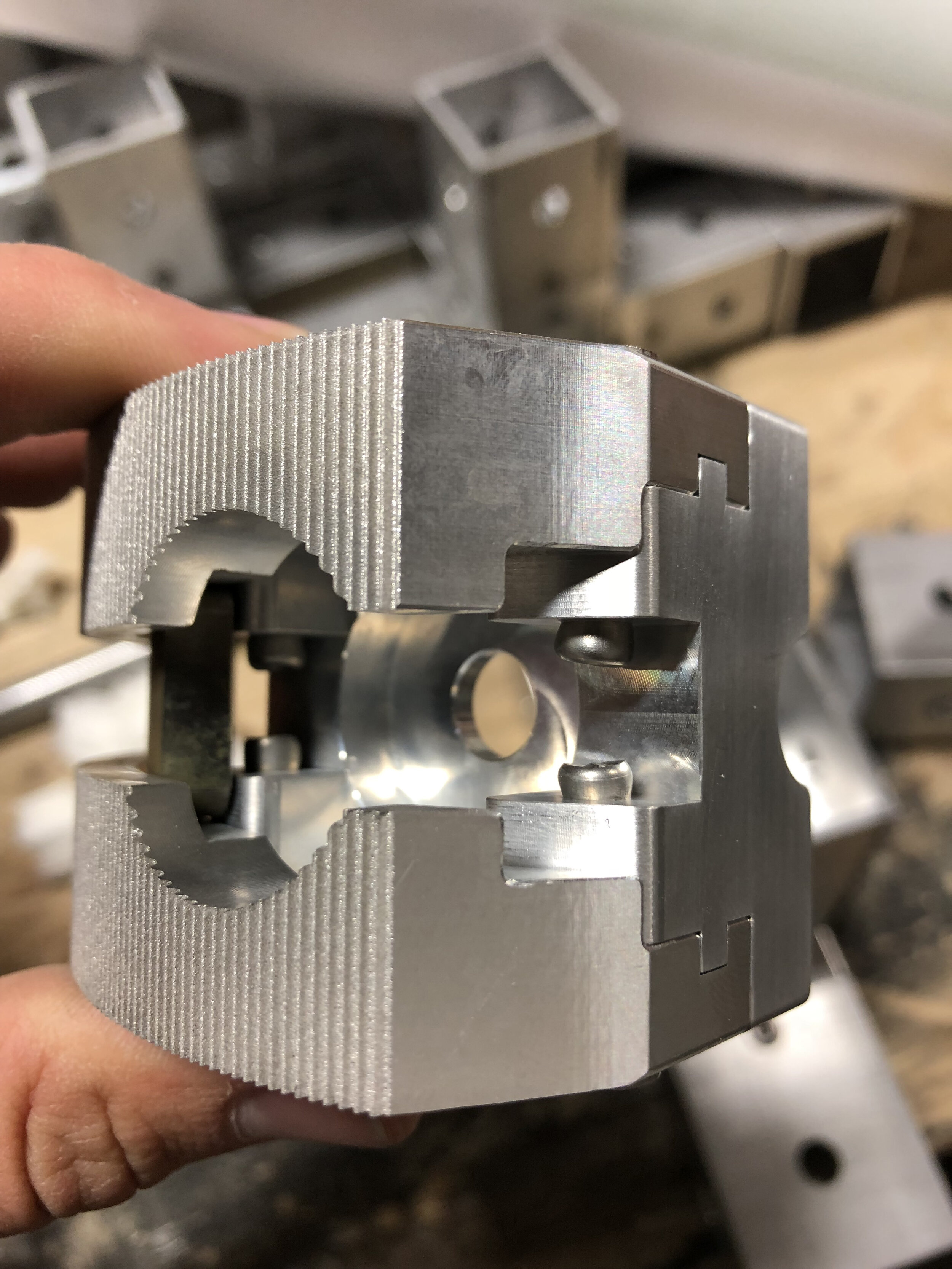

The project landed on a system of milled aluminum node pieces that could accommodate a wide variety of angles. These would be joined together by standard-sized LVL, steel, or aluminum frame pieces, cut as required and joined to the nodes with clevis pins. The whole assembly could be taken apart and re-used after a production run, with the any set cladding being the only pieces requiring storage. Further, because the nodes are the only specialized portions of the kit, sending ballet sets overseas for a tour becomes much more economical. A cut sheet for the standard-sized frame pieces could be sent in advance to the destination, requiring only the node pieces and cladding to be shipped long-distance. Once the tour is over, the frame pieces could be reused or recycled, reducing the amount of waste, expense, and resource use associated with set transport.

The first iteration of the SET ASSEMBLY KIT was used in constructing a portion of the grand staircase in Alberta Ballet’s production of Sleeping Beauty in October 2018.